MARTIN SAMPSON warns of the dangers of neglecting the low- and high-pressure hoses on your dive-kit

I’m going to try to achieve the impossible and make regulator hoses sound interesting. I might have lost some of you right there, but stay with me and you might save a fair amount of money on your next regulator service. As I write this, I have just done an estimate for a service that should have come out at £65-70, but instead will be closer to £160 because of three damaged hoses.

Most regulator hoses cost £25-35, with one or two brands considerably more expensive than that. Beside the cost there’s the risk that a hose failing under water might lead to something far worse – a rapid ascent.

Fortunately, hoses don’t often rupture – after thousands of dives, I can honestly say that the number of hoses I have seen burst number fewer than 10. But that’s not the point – you wouldn’t want a hose to burst once, never mind 10 times.

Overview

Rubber hoses are designed with a large safety factor and have burst pressures about four times higher than their maximum rating of 34 bar. Typical hose construction features an inner liner surrounded by a single, spun polyester cord for reinforcement. Outside is a cover of rubber that should protect the liner from the ravages of abrasion and the environment.

This outer rubber layer can add weight and stiffness to the hose and, frankly, is not the best of materials to withstand the environment in which diving hoses are used. The more a hose is stressed and flexed, the quicker it can dry, crack and break down in the presence of salt, ultraviolet light and atmospheric ozone.

If any of your hoses are cracked or leaking air at the fittings, regard it as failed and replace it without delay. At the very least, get it checked at your local service centre.

In diving, rubber hoses have gradually been superseded by lighter and more flexible hoses manufactured by companies such as Miflex. These hoses feature an inner liner of tough polyurethane, fully covered with a multi-strand braided polyester reinforcement. Above this is a braided nylon outer that is much better suited to the job.

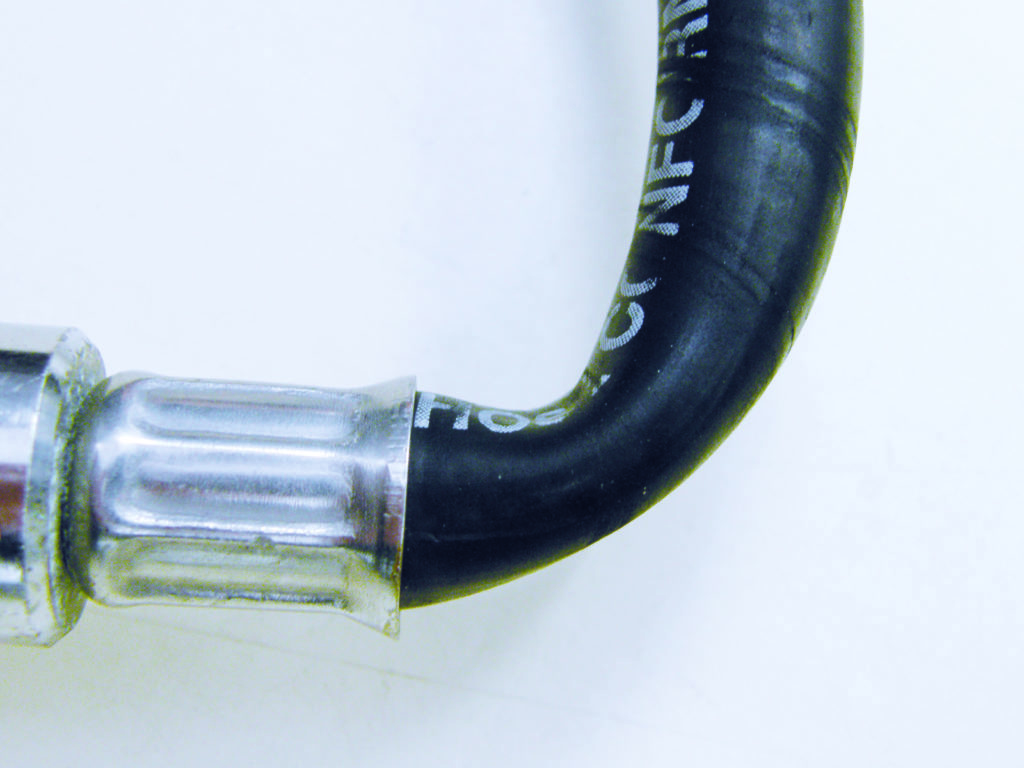

Once cut to length, most hose fittings are attached to the hose-ends with crimped brass ferrules. Some traditional rubber hoses feature a small hole in the ferrule where you can clearly see the rubber of the hose.

If you can’t see the rubber through the hole, the hose is beginning to pull out of the ferrule and might separate catastrophically from the hose-fitting. On the more modern braided flexible hoses, the fittings are specifically designed so that the hose cannot be pulled out of the fittings, which obviously increases safety at this critical point of the hose. Miflex regulator hoses have a burst pressure eight times the normal maximum pressure of 34 bar.

Any stress in the hose, such as that caused by coiling it too tightly, is also concentrated at the ferrule. This is where the majority of hose failures occur.

“Hose protectors” have been available for years; plastic sleeves that slide over the ferrule and hose are supposed to relieve stress in the hose. However, many of these are poorly designed, being either too stiff (especially in cold water) or the wrong shape at the edge. Consequently, the stress is simply moved along the hose.

In addition, many of them don’t allow water to drain, so rather than protecting the hose they do the opposite by trapping salt and promoting corrosion of the ferrule.

If you can avoid stressing your hoses as well as generally looking after them, there is no reason why they shouldn’t last for many years.

8 top tips

1. Use protectors for braided flexible hoses that are easy to remove for cleaning and inspection. When fitting them, don’t push them over the hose-nuts at the first stage. Leave enough room for a spanner so that hoses can be changed without pulling on the hose protector and stressing the hose.

2. Clean and check your hoses on a regular basis, to ensure that you remove any salt and other debris. Look for tell-tale signs of wear from abrasion, especially those nasty cracks in the rubber.

3. Don’t coil hoses too tightly. If you want to use a regulator bag, choose one that will easily accommodate the whole set-up – including an instrument console.

4. Check the height of your BC on the cylinder to make sure that there is enough room for hoses to naturally follow the contours of the jacket, especially when the BC is fully inflated.

5. First stages such as the Scubapro Mk2 have ports that are arranged radially around the valve body, with the result that when all the ports are occupied there is usually one hose that’s stressed. A great accessory for these regulators is a 90° swivel, especially for the BC hose.

Make full use of the ports on balanced first stages by experimenting with the position of the first stage body. The Scubapro Mk25 first stage has five low-pressure ports. including one on the end that is very useful, particularly for the drysuit direct-feed hose.

This useful feature is unique to balanced piston first stages for regulator hoses. However, Apeks came up with a device for its DST balanced diaphragm regulator called the fifth port to overcome this problem. A fifth port is also handy for routeing the shorter direct-feed hoses beloved of sidemount divers.

6. Keep the pressure gauge and the alternative air source hose stowed neatly so that there is little chance of these becoming snagged. One memorable hose-failure I witnessed came when a diver exited a hard boat with a backward roll and then spent the next few seconds suspended by his SPG, which was jammed in a cleat.

7. Some manufacturers offer hoses in a range of lengths, including some custom lengths. This can be useful if, for example, you need a drysuit hose or high-pressure regulator hoses to reach round a 46in chest and size XL BC without being stressed.

8. If you do need to replace damaged hoses, look into using the more modern braided type of hose. It will last longer and is lighter. Both of these features will save you money in the long run.

Finally, make sure that you use only diving hoses manufactured to the EN250 standard. This will be clearly marked on regulator hoses.

Photographs by Martin Sampson

Excellent advice Thank you 😊

Been diving for almost 15 years and this was illuminating. Thanks

Agree with most of the points raised in this article – though I did have an unfortunate experience with an early Miflex hose, so am still in the rubber hose with ridged (internally, for drainage) hose protector camp. Also, how on earth (or underwater) would anyone get that amount of sand on a hose ferrule – unless (oh, no, surely not..!), this was a Staged photo..!

very interesting however long you have been diving